Brake Hub Assembly

- Home

- /

- Brake Hub Assembly

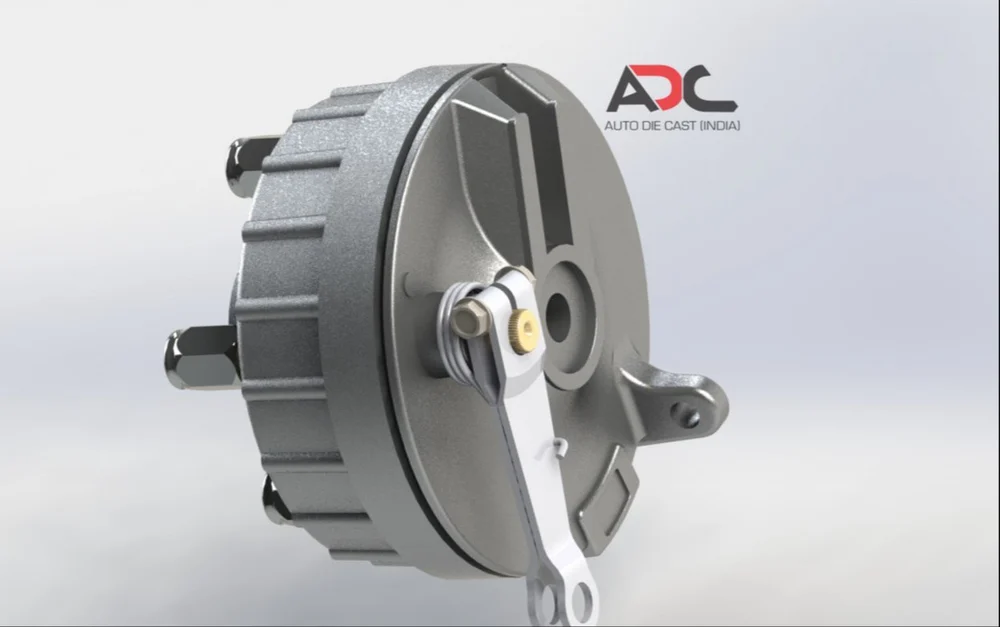

A Brake Hub Assembly is more than just a single part; it is the complete unit that ensures your vehicle brakes effectively and safely. This assembly connects the braking components with the wheel and provides the structural base for consistent and controlled braking. Be it is a bike, e-scooter, or utility vehicle, a quality brake hub assembly makes sure that a smooth braking and long-lasting reliability are achieved.

With Auto Die Cast (India), every assembly you get comes with quality, accurate fit, and functionality that is smooth. As dedicated Compatible Brake Hub Assembly Manufacturers in Delhi, we are aware of how important this part is to both vehicle safety and performance.

Components of a Brake Hub Assembly

|

Component |

Function |

|

Brake Drum |

Rotating part that receives force from brake shoes to stop the vehicle |

|

Hub Shell |

The central body that connects to the wheel and axle |

|

Bearings |

Allow smooth rotation and reduce friction |

|

Studs/Bolts |

Fix the assembly securely to the wheel |

|

Brake Shoes (optional) |

Friction material that presses against the drum to create braking force |

|

Seals/Caps |

Protect internal parts from dust and moisture |

Benefits of a Quality Brake Hub Assembly

- Perfect Fit and Balance: Delivers reliable braking with perfect alignment and smoothness.

- Longer Life Span: Quality components and proper treatment lower the risk of early damage.

- Improved Vehicle Safety: Better control when braking, especially in sudden stops or at high speeds.

- Low Maintenance: With correct fitting and routine inspections, it stays reliable for thousands of kilometers.

- Adaptable for Various Models: Perfect for daily-use bikes such as Revo 110, Boxer 150, and Splendor Plus.

Recognized among the top Suitable Brake Hub Assembly Suppliers and Exporters from India, we at Auto Die Cast (India) offer customized solutions for OEMs, workshops, and manufacturers across India.

Searching for a trusted Brake Hub Assembly? Contact Auto Die Cast (India) now!

Precision. Strength. Performance—All in one assembly.

10,000+

Production Area (Sq. Ft.)

50+

Modern Machines

100+

Engineering Team

50+

Export Countries

Why Choose Us

Total Experience

9+ Years

Brake Parts Delivered

10 Lakh+

OEM Projects Supported

200+

Parts Produced Annually

2 Million+

ADC Precision Manufacturing Process

Certified Raw Material Selection

High-grade aluminum alloys are sourced from trusted suppliers and verified for chemical composition to ensure strength, durability, and consistency in every casting.

Advanced Die Casting Technology

Molten aluminum is injected into precision-engineered dies under controlled pressure to achieve accurate dimensions, smooth finish, and superior integrity.

Precision Machining & Inspection

Each component undergoes CNC machining followed by dimensional inspection to ensure exact tolerances, perfect fitment, and application-specific accuracy.

Quality Assurance & Final Dispatch

Finished products are quality-checked for strength, finish, and performance before being securely packed and dispatched to clients across India and global markets.

Questions About

Our Products

We believe transparency builds trust. Here are answers to the most common questions our clients ask before choosing ADC.

What does Auto Die Cast (India) do?

+Why should I choose Auto Die Cast (India)?

+Do you only make auto parts?

+Can I ask for customised parts?

+E Rickshaw Front Brake Drum

The Keyword helps the vehicle slow down quickly and safely, making sure every ride stays smooth and secure. This part helps keep the vehicle safe by allowing it to slow down and stop well, whether the road is smooth or rough. Known as reliable Compatible Keyword Manufacturers in Delhi, we at Auto Die Cast (India) focus on quality and performance to keep your electric ride safe and smooth.

Electric Scooter Drum Brake

The Keyword is not just a braking component; it is an important safety system tailored to the specific dynamics of electric two-wheelers. Unlike traditional braking systems, drum brakes in electric scooters are engineered to deliver consistent, stable performance while withstanding the regenerative braking effects typical in EVs. Proud to be leading Manufacturers of Keyword in Delhi, Auto Die Cast (India) offers brake systems that are tough, light, and built to handle city roads with ease.

Hub Motor Rear Drum Brake

Each time you brake, the Keyword steps in silently to help bring your electric two-wheeler to a calm, steady stop. This compact brake sits in the rear wheel and quietly does its job, handling bumpy roads while syncing perfectly with the motor. At Auto Die Cast (India), we take pride in being leading Manufacturers of Keyword in Delhi, offering dependable braking systems designed for comfort, safety, and durability.

This drum brake is specially designed for electric vehicles with hub motors. It fits neatly inside the motor housing, making it compact and easy to maintain, perfect for modern electric mopeds, scooters, and bikes.

Electric Scooty Drum Brake

The Keyword works behind the scenes to give you safe, quiet, and reliable stopping power on every trip. It is the round metal component inside the wheel that helps you stop safely and smoothly whenever you need to. If you are riding to work, school, or just around the block, having a good drum brake makes all the difference. As one of the most reliable Compatible Keyword Manufacturers in Delhi, Auto Die Cast (India) delivers solutions that riders and manufacturers count on every day.

We make drum brakes that work perfectly with many different electric scooty models. With a strong grip, minimal noise, and easy fitting, they are built to make your daily rides both comfortable and safe.

Electric moped Drum Brake

The electric moped drum brake is what helps you stay in control when you are riding your moped. It may not be flashy, but this compact and reliable component is what ensures your ride stops exactly when you need it to. At Auto Die Cast (India), we proudly stand among the leading Compatible Keyword Manufacturers in Delhi, offering durable, high-performance brakes trusted by riders and EV manufacturers across the country.

Designed especially for electric mopeds, this brake system provides a great balance of safety, ease of use, and long-lasting functionality. If you are riding in city traffic or open roads, our drum brakes are built to handle the journey with confidence.

Electric bike Drum Brake

Quiet rides are fun, but strong brakes make sure you stay safe when it is time to slow down. The Keyword is a key part of that process. Compact, efficient, and low-maintenance, it helps bring your e-bike to a steady halt without any jerks or noise. As the leading and reliable Compatible Keyword Manufacturers in Delhi, Auto Die Cast (India) offers quality brakes that fit city riding perfectly.

Our drum brakes work great on electric bikes that go slow or medium speeds, making every ride not only safe but also smooth. If you are navigating traffic or gliding down a cycle lane, our drum brakes offer stability and confidence with every stop.

Electric motorcycle Drum Brake

No matter if it is a quick trip or a long ride, your electric motorcycle needs braking you can always count on. That is where the Keyword steps in. It is a compact, enclosed system that provides consistent stopping power without making a fuss. When it comes to Compatible Keyword Manufacturers in Delhi, Auto Die Cast (India) stands out by providing quality parts for safer rides.

Designed for low to mid-speed electric motorcycles, this drum brake is built to deliver balanced performance, long life, and peace of mind—all with low maintenance. Perfect for daily commuters and delivery riders alike, it's a smart solution for smart vehicles.

Loader E Rickshaw Front Brake Drum

When your e-rickshaw is loaded with things, such as goods, parcels, or supplies, then it is important that every stop is steady, safe, and strong. That is exactly why the Keyword plays an important role. Made to handle heavy loads and constant use, this brake drum helps you depend on your electric loader no matter how tough the job gets. Known for quality and durability, Auto Die Cast (India) is one of the top choices as the Compatible Keyword Manufacturers in Delhi.

Our front brake drums are built strong to handle heavy loads and keep braking smooth for a long time. If you are moving through narrow streets or crowded places, you will notice the difference with each stop.

Cargo E Rickshaw Front Brake Drum

When you are carrying cargo on your e-rickshaw, every brake matters. The Keyword helps keep your vehicle steady, especially when carrying heavy loads or driving through busy streets. It is not just a part; it is your frontline defense for safe and steady stops. At Auto Die Cast (India), we take pride in being one of the leading Compatible Keyword Manufacturers in Delhi, known for engineering drum brakes that are tough, reliable, and built for daily use.

Crafted for commercial electric vehicles that haul goods, our brake drums combine durability with smooth braking performance. If you are transporting goods or making stops along the way, a reliable front brake is something you just can not go without.

Cart Front Brake Drum

Utility carts are great for jobs, such as carrying loads and collecting waste, but they also need to be safe, not just strong. With the Keyword, every stop is smooth and safe, so you do not have to worry. Designed to handle frequent use and varying loads, this brake drum plays an important role in protecting both the vehicle and the goods it carries. At Auto Die Cast (India), we proudly serve as leading Compatible Keyword manufacturers in Delhi, offering reliable, heavy-duty brake solutions built for electric and utility cart applications.

Our front brake drums are made for carts that operate in crowded urban areas, industrial zones, and institutional campuses. With performance engineered into every curve and groove, they deliver peace of mind with every ride.

CBS Drum Brake

Think of riding a scooter where a single brake tap brings balanced stopping power to both wheels. That is the magic of the CBS Drum Brake, short for Combined Braking System. It is built to give electric two-wheelers, rickshaws, and carts an extra edge in safety, especially in stop-and-go city traffic.

We at Auto Die Cast (India) understand how important it is to make braking both smarter and smoother. As experienced Compatible Keyword Manufacturers in Delhi, we build drum brakes that bring comfort, control, and confidence to every ride.

Electric Two Wheeler Drum Brake

Two wheelers powered by electricity are transforming mobility with greener, quieter, advanced rides. But one thing that has not changed is the need to stop safely. This is where the Keyword plays its role. A proven solution, it lets riders brake smoothly if they are navigating busy streets or slipping through narrow alleys, and control and safety are always within easy reach.

Products made at Auto Die Cast (India) solely focus on safety and long-lasting performance. Proudly working as Compatible Keyword Manufacturers in Delhi, we offer durable, easy-to-use brakes for EV riders.

EU Certified Drum Brake

Every brake stops a vehicle, but few do it right. If you value quality and global certification, the Keyword rises above the rest with proven safety. Designed and tested to meet European Union regulations, this brake system makes sure that your electric vehicle not only performs reliably but is also road-legal for international markets.

At Auto Die Cast (India), we create amazing brake solutions, which are especially designed to surpass everyday performance needs. As one of the best Manufacturers of Keyword in Delhi, we give high-quality materials, regular testing, and also strict quality control to fulfill EU standards. Whether it is for scooters, bikes, or motorcycles, our drum brakes are made to earn your trust and Europe’s stamp of approval.

EV Drum Brakes Meeting IS Standards

Safety plays an important role, especially when it comes to electric vehicles. That is the reason Keyword are gaining trust from reliable manufacturers. These brakes follow Indian Standards (IS), showing that they are not only reliable, strong, but also long-lasting.

At Auto Die Cast (India), we proudly serve as leading Manufacturers of Keyword in Delhi. We design our brakes to do more than stop; they deliver safe, smooth, and steady performance, rain or shine, every time you ride.

ARAI Approved Brake

When it comes to electric vehicles, keeping everyone safe is a big responsibility. That is why Keyword are trusted. ARAI, the Automotive Research Association of India, checks that brakes work well and last long. If a brake is ARAI approved, it means it has been tested for safety, durability, and reliability on real Indian roads.

At Auto Die Cast (India), leading Compatible Keyword Manufacturers in Delhi, we provide safe and reliable braking options for electric scooters, e-rickshaws, and mopeds. ARAI certification brings trust and quality, no matter if your products are for India or other countries.

Bike Drum Brake

When you're on the move, your safety depends on one main feature, and that is braking. A Keyword is a popular and trusted solution for everyday riders who want smooth and controlled stops without complicated maintenance. It works well for both traditional bikes and modern electric two-wheelers, especially in city conditions.

Our team at Auto Die Cast (India) focuses on building high-quality braking systems. Being trusted Manufacturers of Keyword in Delhi, we build drum brakes that can handle not only rough roads but also last a long time. And if you are an OEM or a vehicle assembler, our brakes help make sure that you get a dependable riding experience.

Brake Hub

A Keyword plays an important role in how safely and smoothly a vehicle stops. It connects the wheel and braking system, allowing the brake shoes to apply force inside the drum and bring the vehicle to a halt. Whether you're riding a two-wheeler, delivering goods on a three-wheeler, or operating an EV, a reliable brake hub ensures consistent performance on every trip.

A well-built hub is very important, and at Auto Die Cast (India), we understand that. As one of the leading Compatible Keyword Manufacturers in Delhi, we provide durable and precision-engineered brake hubs suitable for a wide range of vehicles and driving conditions.

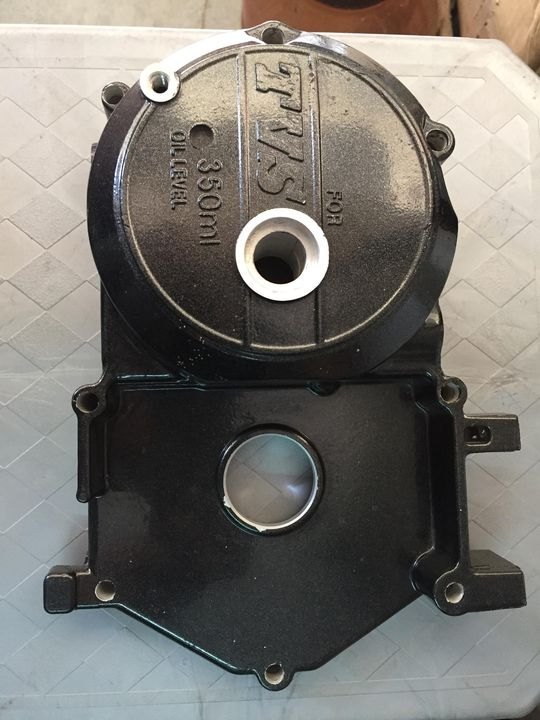

Brake Hub Assembly

A Keyword is more than just a single part; it is the complete unit that ensures your vehicle brakes effectively and safely. This assembly connects the braking components with the wheel and provides the structural base for consistent and controlled braking. Be it is a bike, e-scooter, or utility vehicle, a quality brake hub assembly makes sure that a smooth braking and long-lasting reliability are achieved.

With Auto Die Cast (India), every assembly you get comes with quality, accurate fit, and functionality that is smooth. As dedicated Compatible Keyword Manufacturers in Delhi, we are aware of how important this part is to both vehicle safety and performance.

Brake Hub Replacement

Over time, your vehicle’s braking performance can take a hit due to wear and tear. One of the most important components that may require attention is the brake hub. A Keyword makes sure that your wheels and braking system remain properly aligned and fully functional, giving you safer and smoother rides every day.

At Auto Die Cast (India), we understand how important a reliable replacement is. As one of the trusted Manufacturers of Keyword in Delhi, we produce quality-assured brake hub units that match OEM standards and fit a wide range of two-wheelers and electric vehicles.

Brake Lever

A Keyword may look small, but it plays an important role in keeping riders safe. It is the part you pull to slow down or stop your two-wheeler, giving you full control over your ride. Whether you are going through traffic or navigating tricky turns, a responsive brake lever makes all the difference.

When it comes to durability and fit, Auto Die Cast (India) stands out with levers built for almost every bike and scooter on the road. Known among the best Compatible Keyword Manufacturers in Delhi, we create robust levers engineered specifically for the needs of local commuters.

Brake Lever Replacement

The brake lever is your bike’s quick response tool for safety, letting you hit the brakes exactly when a traffic jam or tight corner appears. But over time, brake levers can wear out, get bent, or lose sensitivity. That is where a keyword becomes important.

We at Auto Die Cast (India) offer high-quality, vehicle-specific solutions for two-wheelers across India. As experienced Manufacturers of Keyword in Delhi, we know that every replacement should feel just like the original and that it is smooth, responsive, and reliable.

Brake Lever Fitting

When it comes to two-wheelers, your brake lever is not just a handle; it is your main safety control. At Auto Die Cast (India), we specialise as trusted Manufacturers of Keyword in Delhi. Whether you are upgrading or replacing, the right fit makes all the difference.

Brake lever fitting is the process of securely attaching the lever that connects you to your vehicle’s braking power. A lever that is installed properly makes sure that the right pressure is applied to the brake mechanism, provides the riders with reliable stopping power, and full control. An incorrect fit might seem small, but it can lead to major problems like weak or failed braking when you need it most.

Brake Lever Right Side

The right side brake lever plays an important role in the braking system of a two-wheeler. It is commonly used to operate the front brake; this lever helps deliver quick and smooth braking on bikes and scooters. Whether you are upgrading or replacing a worn-out lever, the Keyword needs to fit perfectly and function flawlessly.

At Auto Die Cast (India), we manufacture precision-engineered levers that suit a wide range of models. As the reliable and known Manufacturers of Keyword in Delhi, we understand the importance of safety, fit, and durability in every ride.

Brake Lever Set

The right side brake lever contributes significantly to the safety and performance of your two-wheeler’s braking system. They are mostly used for controlling the front brake in motorcycles and scooters. This lever gives smooth and responsive braking performance when it matters most. Whether you are upgrading or replacing a worn-out lever, the Keyword needs to fit perfectly and function flawlessly.

At Auto Die Cast (India), we manufacture precision-engineered levers that suit a wide range of models. We are known as the eminent Manufacturers of Keyword in Delhi, we understand the importance of safety, fit, and durability in every ride.

Brake Lever Spare Parts

At Auto Die Cast (India), our expertise lies in crafting lever sets with precision engineering to offer seamless compatibility with most two-wheelers. Known as reliable Compatible Keyword Manufacturers in Delhi, we design every component to be strong, effective, and ready for the road ahead.

The left and right levers in a Keyword are designed to function as a pair, offering stable and effective braking. No matter what you are riding, be it a scooter, moped, or motorcycle, having a matched set offers a consistent feel and operation on both sides of your handlebars. From short city rides to long highway journeys, the right Keyword can noticeably improve how safe and comfortable your ride feels.

Brake Panel Assembly

At Auto Die Cast (India), we understand how essential each component of your braking system is. That is why we focus on precision and durability as leading Manufacturers of Keyword in Delhi. Our spare parts are designed to fit perfectly and restore braking efficiency, whether you're riding a daily commuter or a rugged utility bike.

Keyword are the smaller components that make up or support the function of a complete brake lever system. These parts make sure the lever moves smoothly, activate the brakes precisely, and last through everyday use. From pivots and brackets to lever arms and springs, each part is important for keeping your brakes safe and reliable.

Brake Panel Rear Fitting

Respected in the field, Auto Die Cast (India) produces high-performance components valued by OEMs and two-wheeler professionals. As one of the leading Manufacturers of Keyword in Delhi, we focus on precision engineering, robust materials, and model-specific fitting. Whether you are looking for a Sport Keyword or a unit for your Star City Plus, we offer assemblies that meet the highest safety standards.

The Keyword is a critical component of a drum brake system. Positioned inside the brake drum, it acts as a mounting base for other braking parts and ensures their alignment during braking. In simpler terms, it holds everything together, brake shoes, springs, camshaft, and other parts, so your braking system functions smoothly and safely.

Brake Panel Rear Side

At Auto Die Cast (India), we focus on delivering precisely engineered components that serve both performance and safety. As one of the leading Manufacturers of Keyword in Delhi, we make sure that every unit is crafted with attention to fit, strength, and compatibility.

Designed for various two-wheeler models, our Keyword products consistently provide dependable function under diverse road and usage scenarios.

The Keyword is vital for the proper functioning of the drum brake system in motorcycles and scooters. It acts as the structural base that houses important rear brake components such as brake shoes, actuating levers, springs, and cams. This component makes sure that the braking action is stable, aligned, and safe for the rider.

Brake Panel Replacement

When it comes to keeping your two-wheeler’s brakes performing at their best, the brake panel is far more important than many riders think. We at Auto Die Cast (India) create strong, precision-fit components made to perform on motorcycles and electric rides. As one of the prominent Compatible Keyword Manufacturers in Delhi, we provide quality solutions that meet performance expectations and safety standards alike.

The brake panel is a foundational part of a drum brake system. It houses the brake shoes, camshaft, springs, and other supporting components. Over time, due to regular wear and tear or accidental damage, the brake panel may lose its efficiency or alignment, leading to compromised braking performance. Replacing the brake panel is a very important step in restoring both safe and smooth braking, especially in daily-use vehicles and electric bikes.

Brake Panel Spare Part

We build reliable and durable brake parts at Auto Die Cast (India), designed especially for the demands of today’s vehicles. As one of the most trusted Compatible Keyword Manufacturers in Delhi, we create parts that are strong, dependable, and long-lasting. On top of this, we are proud Suitable Keyword Suppliers and Exporters from India, providing value you can always count on. This is because we make brake yokes carefully designed for two-wheelers and scooters, giving you great braking control in every ride.

A Keyword might be a small part, but it is an important part of the braking system that moves force from the brake pedal or lever to the brake rod. It helps make sure the brake system works properly by providing a strong and steady connection. Whether you are looking for a Boxer At Brake Yoke, AR Brake Yoke, or a model-specific yoke like Activa Brake Yoke or CT 100 Brake Yoke, we offer a wide range suited for various two-wheeler models.

Brake Plate Assembly

When making sure that your vehicle is both safe and simple to control, every part is important, and this mainly goes for the brakes. We at Auto Die Cast (India) know just how crucial a strong and well-engineered brake plate assembly is for braking that works well. As one of the leading Compatible Keyword Manufacturers in Delhi, we provide assemblies that are precision-built to support consistent braking performance across various two-wheeler models.

The Keyword is a core part of drum brake systems that keeps all the parts in place and working right. It holds the brake shoes and other parts tightly so the shoes can spread out and create the friction needed to stop the wheel. This part works in both front and rear drum brake systems. It needs to be strong, keep rust away, and fit perfectly with the drum to function properly.

Brake Yoke

When it comes to keeping your two-wheeler safe and running well, each and every part truly matters. We at Auto Die Cast (India) are committed to strength, precision, and trust, especially in brake components. We have been leading in this industry for a long time, and are well-known as one of the Compatible Keyword Manufacturers in Delhi. This is because we provide spare parts that are model-ready, purpose-built, and carefully tested to offer both safety and performance.

Within a vehicle’s braking setup, the Keyword stands out as the most important component in use. Placed within the wheel hub, the brake panel helps fit brake shoes and handles pressure from the brake lever. With time, brake panels wear from regular use, tough conditions, or small bumps, so replacing them keeps your brakes safe and working just like new.

Clutch Cover

At Auto Die Cast (India), we know every part that makes up a two-wheeler device is integral and should be constructed very aptly. The two-wheeler Keyword is very integral despite its simple appearance. We are well-known as Compatible Keyword Manufacturers in Delhi, and not only this, but we are also proud to say that we are one of the best Suitable Keyword Suppliers and Exporters from India. We know how to manufacture the clutch with proper durability for sealing and long-term durability and functioning of the two-wheelers, be it mopeds, scooters, or motorcycles.

The Keyword is an integral part of the two-wheeler outer casing of the engine. It is placed at the side of the transmission system. The Keyword protects the clutch assembly to some level, shielding it from harmful dirt, as well as protecting against oil drainage. It is in the clutch system to ensure that its guardant layer is in place, as well as guarding the clutch system to maintain its interchange.

Clutch Cover Casing

In motorcycles and scooters, performance enhances with precision and each component plays an integral role. We take pride in being one of the leading Compatible Keyword Manufacturers in Delhi, as we ensure best precision-engineered Keyword solutions. With us, vehicle control, rider comfort, and safety can be achieved in a sustained manner.

Range of two-wheelers, performance scooters, and commuter bikes all require clutch levers and their fittings. With our solutions, the rider can smoothly control the clutch and achieve optimum performance and long-lasting durability.

Clutch Lever Replacement

A clutch lever assembly is made up of the lever, holder, adjuster, and pivot pieces, which help manage the clutch system on bikes and scooters. It links the rider’s hand movement to the clutch cable and gears, helping the clutch open and close smoothly when changing gears. As the top clutch lever assembly Manufacturers in Delhi, we combine high-quality materials and precise tools to deliver parts that fit great and stand the test of time.

Unlike singular clutch levers, this full unit is tested and matched to ensure ease of fitting, function, and work. Whether you need to service or replace a damaged part, full assemblies will always ensure consistent factory-accurate reliability.

Clutch Lever Fitting

At Auto Die Cast (India), we understand that every component is key to providing safety and comfort during your ride. As well-known Compatible Keyword Manufacturers in Delhi, we deliver clutch levers that fit perfectly and work reliably, helping your vehicle’s transmission run smoothly again.

From simple scooters to powerful motorcycles, our Keyword are designed to OEM standards, making not only installation easy but also performance trustworthy.

Clutch Lever Assembly

At Auto Die Cast (India), we understand that every component is key to providing safety and comfort during your ride. As well-known Compatible Keyword Manufacturers in Delhi, we deliver clutch levers that fit perfectly and work reliably, helping your vehicle’s transmission run smoothly again.

From simple scooters to powerful motorcycles, our Keyword are designed to OEM standards, making not only installation easy but also performance trustworthy.

Clutch Lever Spare Parts

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Clutch Lever Repair Kit

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Clutch Yoke

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Coupling Hub

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Drum Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Drum Brake Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Drum Brake Rear Wheel

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Drum Brake Shoe

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Drum Brake System

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Drum Brake Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Spare Parts

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Hub Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Hub Plate

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Hub Replacement

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Lever Replacement

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Lever Spare Parts

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Plate Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Replacement

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Panel Kit

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Wheel Brake Hub

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Panel

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Panel Replacement

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Plate

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Shoe Plate

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Brake Drum Shoe Set

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Drum Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Front Drum Plate

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Handicapped Electric Scooter Drum Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

ICAT Approved Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Is 14664 Compliant Drum Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Is 11852 Compliant Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Motorcycle Drum Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Motorcycle Rear Brake Drum

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Motorcycle Front Brake Drum

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Natrax Approved Brake

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Hub

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Drum

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Hub Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Drum Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Drum Replacement

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Hub Plate

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Hub Spare Parts

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Panel Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Panel

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Plate Kit

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Shoe Plate

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Shoe Set

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Drum Plate

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Sprocket Coupling Hub

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Scooter Rear Brake Drum

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Scooter Front Brake Drum

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Sprocket Hub

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Sprocket Hub Fitting

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Sprocket Hub Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Sprocket Hub Replacement

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Sprocket Hub Spare Parts

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Sprocket Hub For Rear Wheel

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Manufacturers of Keyword in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Sprocket Hub Rear Wheel

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Rear Brake Lever Assembly

We at Auto Die Cast (India) design and manufacture every Keyword in a way that meets all the needs of both two-wheelers and three-wheelers. They are made with accuracy and care; every Keyword we make meets the quality standard and customer satisfaction. In addition to this, we are also known as one of the trusted Compatible Keyword Manufacturers in Delhi. We make sure that every Keyword we deliver gives smooth performance, comes with long-lasting durability, and a perfect fit. We understand that each and every part plays an important role in making sure that the vehicle is not only safe, comfortable, but also reliable, and this is why our every keyword is made using the best and advanced technology, goes through strict quality checks, and uses the finest materials.

Specialised Solutions

Electric 2 Wheeler Solution

As the trusted Electric 2-Wheeler Solution Manufacturers in Delhi, Auto Die Cast (India) is proud to offer cutting-edge solutions for the fast-growing electric mobility sector. Our Electric 2-Wheeler Solution is designed to make everyday travel easier, cleaner, and more efficient for people of all ages. Today, with petrol prices going up and pollution getting worse, choosing electric rides is not just smart, it’s something we really should do.

We bring together smart technology and great quality to help businesses build eco-friendly rides like e-bikes and e-scooters. Being one of the leading Manufacturers of Electric 2-Wheeler Solution in Delhi, we focus on making reliable and strong products for great performance.

L3 Electric Vehicles Solution

The future of urban transportation is being shaped by Auto Die Cast (India) every day. As the leading L3 Electric Vehicles Solution Manufacturers in Delhi, we offer not only advanced but also eco-friendly mobility systems that support safer, smarter, and cleaner commuting across cities.

An L3 electric vehicle solution refers to a smart and compact three-wheeler electric mobility option typically used for passenger or light cargo transport. These vehicles are battery-powered, zero-emission, and designed for short-to-medium distance travel, especially in urban and semi-urban settings. They provide a smooth combination of strong performance, savings, and green benefits

Approved & Certified Drum Brakes